The Kinetic Blowout Stopper, or K-BOS, is a retrofittable, large bore electrically initiated, pyro-mechanical gate valve which performs the critical function of shearing and sealing during drilling, completions and intervention well control operations.

The K-BOS is designed to shear anything above the bit, and seal instantly no matter the flow – no exceptions. The industry’s first true blowout “stopper” as opposed to current “preventers” – “think of it as the airbag for the oil & gas industry”.

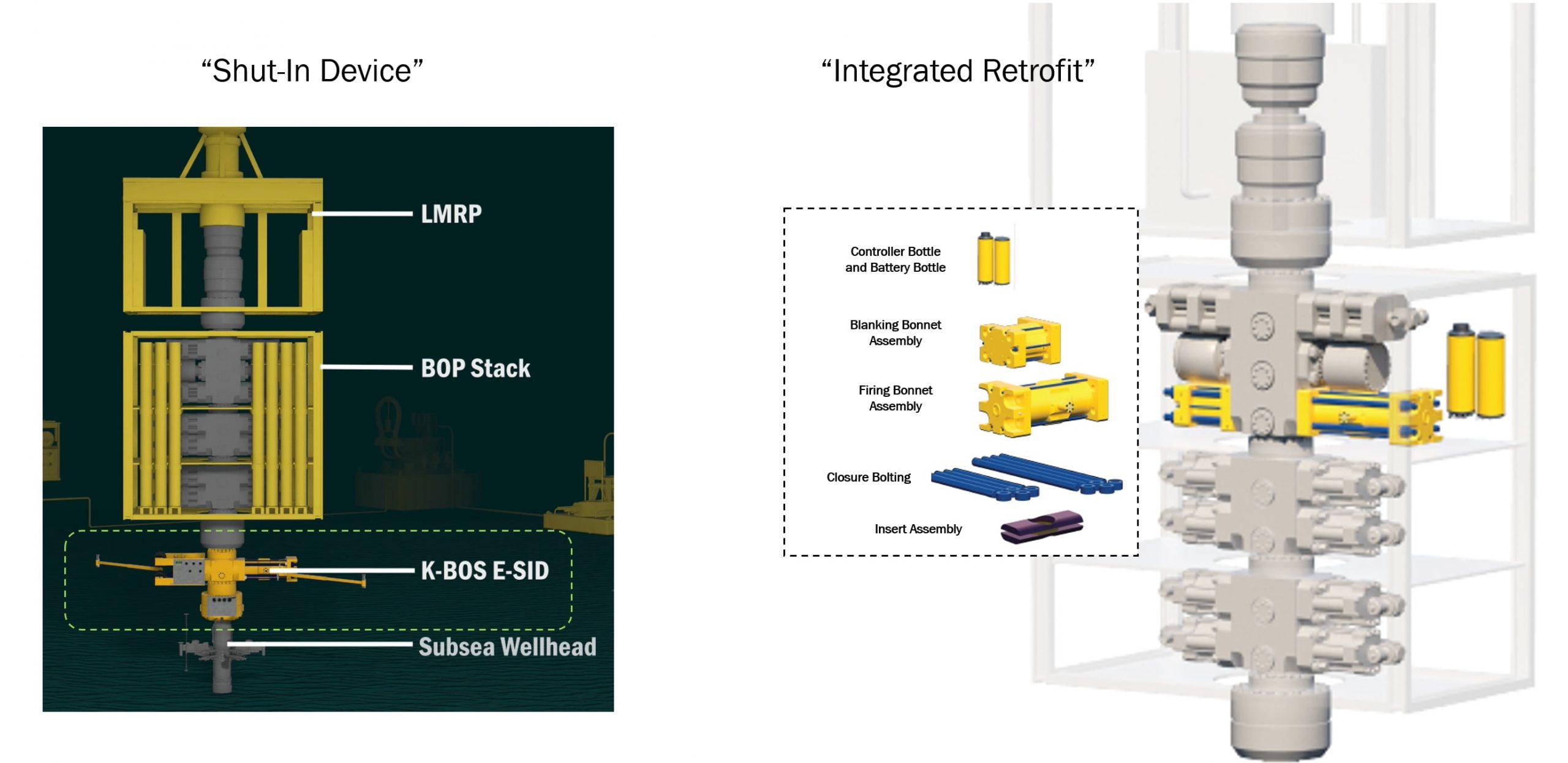

For subsea applications, the K-BOS may be retrofitted to casing shear ram or blind shear ram cavities without disturbing the existing BOP body. Due to its use of pyrotechnics instead of hydraulics, the K-BOS eliminates the need for many subsea accumulator bottles (and their associated weight and maintenance) from the subsea BOP stack. The K-BOS may also be deployed independently of the rig, latched-up directly to the subsea wellhead with the subsea BOP stack latched up above. An overview of this independent configuration may be found towards the bottom of this page.

The primary K-BOS control system is mounted subsea and may operate independently from the surface control systems while allowing for full integration into existing emergency disconnect sequence (EDS) modes and dead-man auto-shear (DMAS) functionality. With the ability to eliminate unshearable and unsealable situations, the K-BOS provides an order of magnitude reduction in enterprise risk posed by blowouts.

This game changing capability combines with the ability to secure the well in a handful of seconds to enable subsea drillers to reimagine dynamic positioning watch circles in deep water, hazardous environments and shallow water.

Transocean’s Deepwater Invictus has successfully tested KBOS (Kinetic Blowout Stopper), shearing a 6 5 8 V 150 50 lbs /ft drill pipe at a depth of 2 400 feet During the field test, the tool performed exactly as designed This wraps up a four month operational deployment of KBOS in a subsea BOP stack ..“KBOS has certainly proven its reliability and is the way of the future for safe operations,” said Sam Covington, Manager of Well Control Equipment, Gulf of Mexico, at Transocean Watch the video to learn more

The K-BOS has been fully tested subsea in the Gulf of Mexico In the video above, you can see the K-BOS together with a next generation subsea control system integrated into what is called the aShear system mounted on an LMRP frame and connected to a double body BOP The equipment was submerged to a depth of 5 100 ft where extensive accelerated lifecycle testing was performed At the end of more than 5 years worth of accelerated testing, the ROV was used to trigger the DMAS circuit The aShear system activates the K-BOS which instantly shears the tubular in the wellbore and, after the tubular falls away into a catch basket, the aShear then closes and locks the blind shear ram.

The K-BOS is rated to shear all typical tubulars, tool joints, heavy casing, landing strings, and BHAs used for a given bore size and can also cleanly shear wireline in the slack condition. The rapid kinetic shearing action leaves a clean fish with minimal deformation and allows the K-BOS to shear and seal in milliseconds with unmatched reliability.

18-15M K-BOS 0.125” Slick Line

0.3125” Braided E-Line

18-15M K-BOS 6.9” OD Slip Proof Landing String, V150

(Side Load & Compression)

18-15M K-BOS 8.5” OD Tool Joint Landing String, V150

18-15M K-BOS 9.5in Drill Collar, 214ppf, MYS120

18-15M K-BOS 16” OD HP Casing, Q125 w/

6.625” OD Inner String, V150; Combined 186ppf

18-15M K-BOS 18” OD HP Casing, Q125 w/

6.625” OD Inner String, V150; Combined 167ppf

In addition to the integrated retrofit, the K-BOS can be deployed subsea as a rig independent Emergency Shut-in Device, or “E-SID” which is mounted on the subsea wellhead with the BOP stack latched-up above the E-SID.

This configuration allows the game changing shear and seal capabilities of the K-BOS to be deployed rapidly and without integration into the rig for short-term engagements. The completely independent E-SID configuration also allows the K-BOS to serve as an 18-3/4” bore 15ksi rated barrier to enable open water intervention and abandonment operations. The E-SID may also be deployed as a capping stack enhancement.

The video below provides an overview of the K-BOS E-SID configuration and outlines that particular value case in more detail.

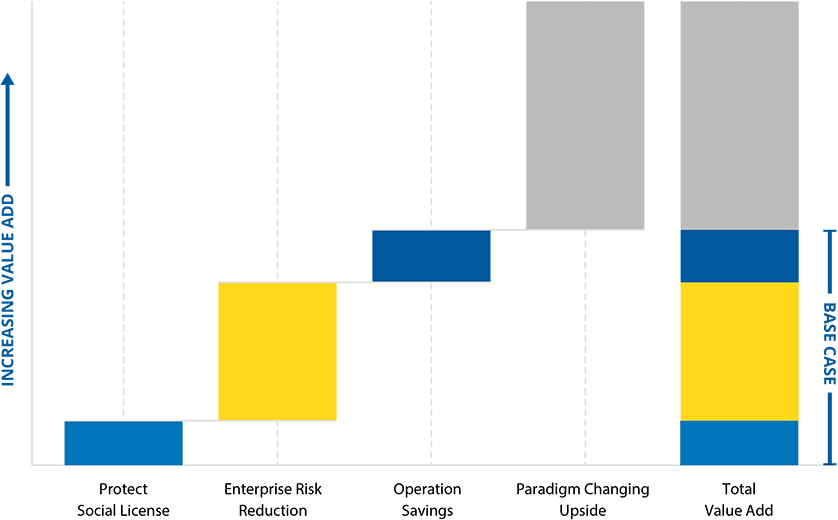

K-BOS Value Case Summary – Subsea Applications

In the past, the Industry’s emergency well control systems lagged reliability standards of comparable safety functions in other industries. The K-BOS utilizes the highest reliability components and methodologies field proven in safety critical applications during more than 20 years. It’s ability to continuously self-diagnose faults and positively confirm functional availability in real time and while offline to operations creates an opportunity to reduce testing related non-productive time while increasing emergency well control system reliability by 3 to 4 orders of magnitude.

The K-BOS provides a drastic improvement in reliability combined with the ability to stop a full flowing blowout. By eliminating exposure to “unshearable” and “unsealable” situations, the K-BOS provides Operators with a dramatic reduction in Enterprise Risk posed by subsea blowouts. There is significant upside value potential as the K-BOS is adopted across the industry creating the potential for changing the overall well control cost paradigm and allowing for more sustainable and profitable growth in the industry.

Here to protect and strengthen the oil and gas industry’s social license to operate.