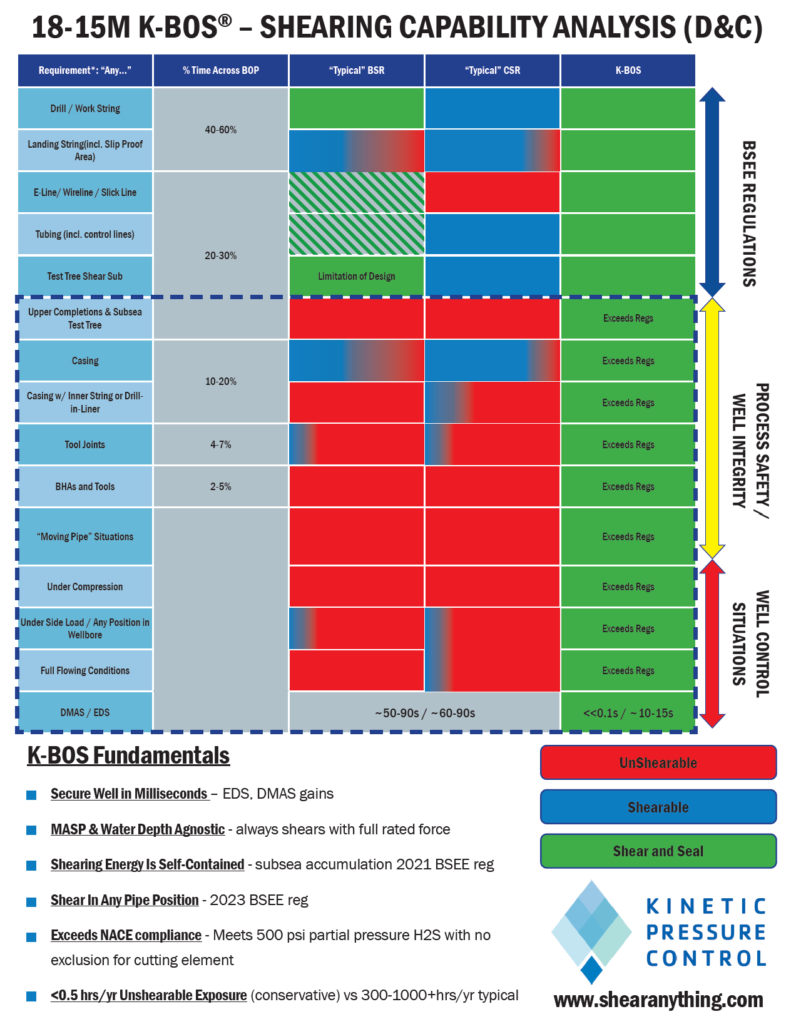

Houston TX: Recent analysis with key partners shows that the K-BOS creates significant operational gains while helping E&P operators and rig owners meet the BSEE regulatory requirement to be able to shear and seal at MASP with two BOP rams in a DMAS or EDS situation. The K-BOS is rated to shear anything and seal instantly at depths down to 12,500 ft water depth and under high flowing conditions at MASP up to full rated working pressure and temperature of 15,000 psi and 350F.

The K-BOS eliminates essentially all unshearables from a given drilling program. Before running a BHA, long heavy casing, or other long unshearable through the BOP stack it is common practice to perform a flow check: requiring about 20 minutes of “non-productive time” or NPT per flow check. Also, the DMAS system is disarmed and the “Emergency Disconnect Sequence” or EDS is placed into a mode that will allow a disconnect without shearing the tubular nor securing the well. Also, the drilling rig’s DP system is typically placed into open bus mode which is far less fuel, maintenance and emissions efficient than closed bus operations. There is also the potential for human error when making these changes to critical systems. All of these compromises and provisions are eliminated by the K-BOS ability to shear anything and seal instantly. The results can be summarized as follows:

Risk Reduction:

- Reduction in the probability of a blowout by 3 to 4 orders of magnitude effectively eliminating an Operator’s largest enterprise risk.

- The system is SIL3 rated per NOG-OLF-070.

- Eliminate the potential for human error from system changes related to running unshearables: DP configuration, arm/disarm DMAS, EDS modes

Operational Gains:

- Ops gains from removal of flowchecks prior to running unshearables: currently estimated to be up to ~60hrs per rig per year or 20 mins per flowcheck conducted typically before BHA, casing string or other long unshearable is run through the stack.

- Ops gains from simplified subsea test tree design and running that could save between 12-36hrs per well of setup and running time

- Reduction in DP related waiting periods/NPT with larger DP watch circles (yellow and red) that can increase DP drilling uptime. This is very dependent on site DP conditions i.e. harsh environments, shallower depths or strong sea currents. At the extreme, it can be an enabler for DP drilling operations.

- Eliminate NPT related to CSR/BSR function, stump, latchup and DMAS drawdown testing (depending on which BOP ram is replaced)

- True NACE rating up to 500psi partial pressure H2S (NACE upper limit) without requiring any exemptions which are typically used for BOPs. At the extreme, it can be an enabler for drilling Ops.

- Optimized well and completion construction without shearing limitations, enabling larger, simpler or more suitable designs to improve well economics

- Improved “LHS of the bowtie” well control measures allows re-think of “RHS of the bowtie” well emergency response plan related to source control, relief well drilling contingencies especially for greenfield operations.

BSEE Shearing Regulations: The K-BOS’s shearing energy is self-contained and independent from a given drilling rig’s existing hydraulic accumulator system. The K-BOS can perform the first shear in a DMAS or EDS situation and remove the biggest consumer function from the requirements on the accumulation system resulting in a dramatic increase to the shearing and sealing capability of existing systems without adding accumulation or making other changes to their equipment. The simple and minimal scope of a K-BOS retrofit allows the rig owner to future proof their primary revenue producing assets to meet the regulatory requirements now and in the future with the best available and safest shearing and sealing technology.

Environmental Impact: Corresponding savings from reductions in fuel burn and carbon emissions from optimized closed bus DP ops due to elimination of unshearables.

- Estimated at 400MT of fuel savings and up to 3,000 engine hours savings from reduced Open Bus DP Operations – This provides a reduction in fuel costs of approx. $200,000/yr and 1000MT CO2 emissions along with engine maintenance savings for the Drilling Contractor.

- Corresponding savings from reductions in fuel burn and carbon emissions from finishing each well earlier

Cost/Benefit Analysis: The combined ops gains and risk reduction from increased shearing and sealing capability results in a cost neutral or low overall cost impact over a 12 month period for a given rig with the near elimination of surface loss of well control risk by 3-4 orders of magnitude.

Please review the following summary of our analysis for more details:

About Kinetic Pressure Control

Kinetic Pressure Control is a leading well control technology company that designs and manufactures innovative wellhead and pressure control equipment and services. Kinetic’s mission is to protect the Oil and Gas industry’s social license to operate. Learn more about Kinetic Pressure Control Limited and their K-BOS technology at www.shearanything.com

Shear Anything | Seal Instantly | Ultimate Reliability