Unmatched Shearing and Sealing

+ Unmatched Component Integrity

= the Ultimate in Safety

With significant operational experience in the Middle East, the field proven K-BOS technology can enable high-risk well interventions and drilling near sensitive areas.

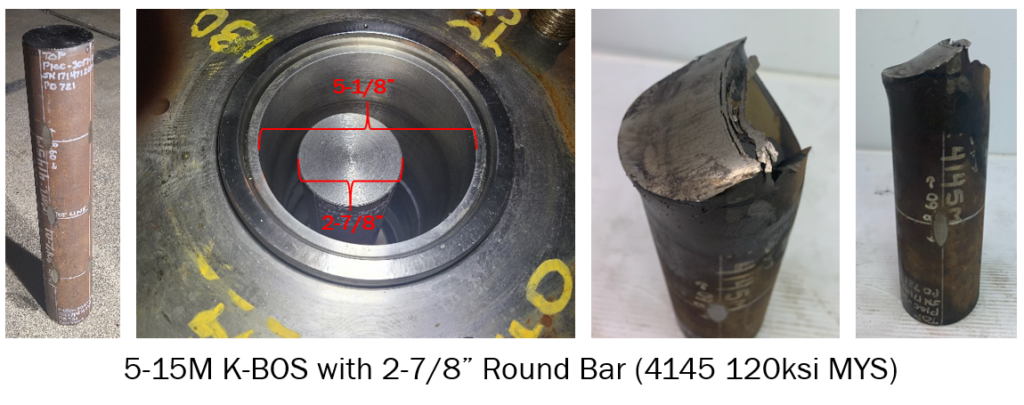

Shown above: the 5-15M K-BOS rigged-up as a safety head prior to rig up of the typical PCE on top of the K-BOS.

The following design capabilities of the K-BOS offer superior protection to work site personnel and surrounding communities in the case of an H2S release:

- Shear and Seal on any typical work string, tool or BHA

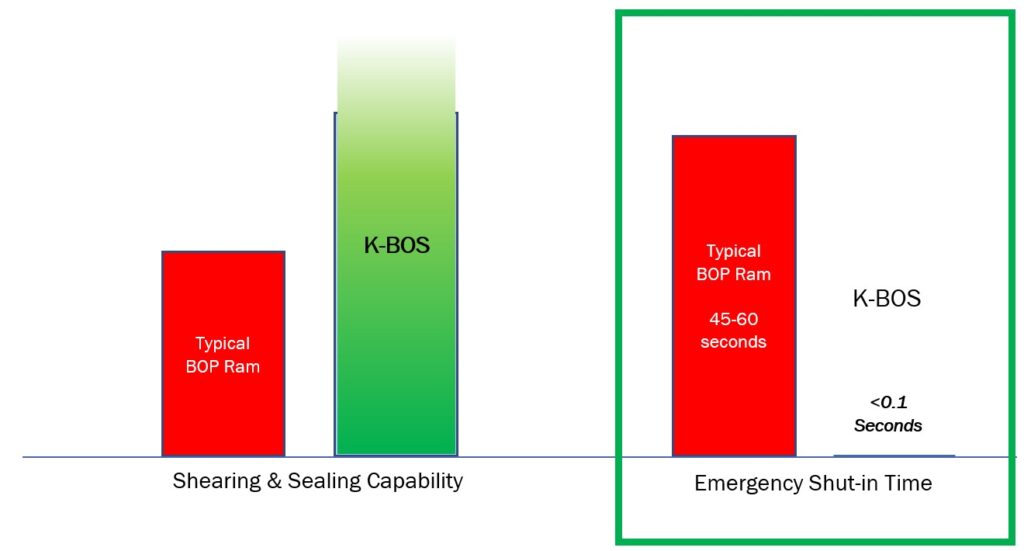

- Shear and seal in milliseconds VS conventional BOPs which require ~ 45-60 seconds

- Component Integrity:

- Isolated working components w/ well bore isolation compatible w/ unlimited H2S

- Sealing elastomers qualified for up to 50% H2S at 350F

Shown above: Shear test results for the 5-1/8″ 15,000 psi K-BOS for CT/WL/SL service.

The K-BOS can dramatically reduce toxic gas exposure times and reduce potential gas volumes released to nearly nil.

Shown above: a chart illustrates the relative shearing a sealing capability of the K-BOS vs traditional PCE. The K-BOS can shear anything and seal instantly.

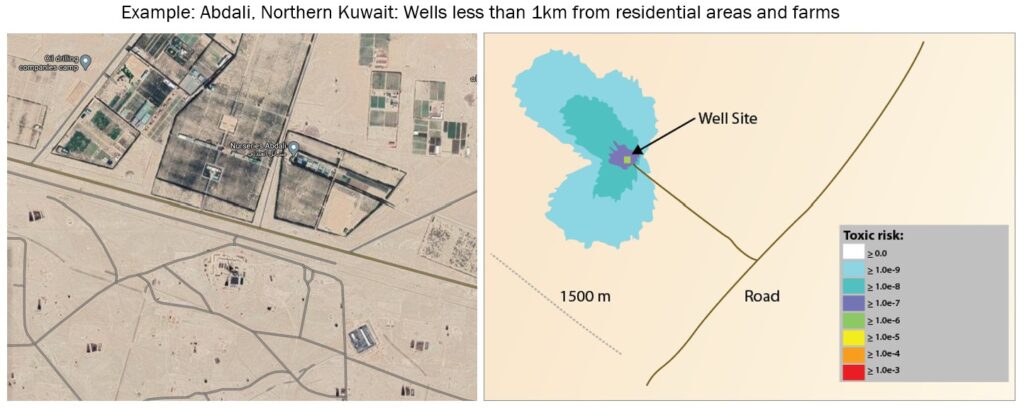

The K-BOS enables simultaneous contiguous high-risk well operations in sour reservoirs as well as enable safe operations near populated areas.

Shown above: many oil fields are in close proximity to residential or industrial areas and are subject to risk of toxic release in the case of a blowout.

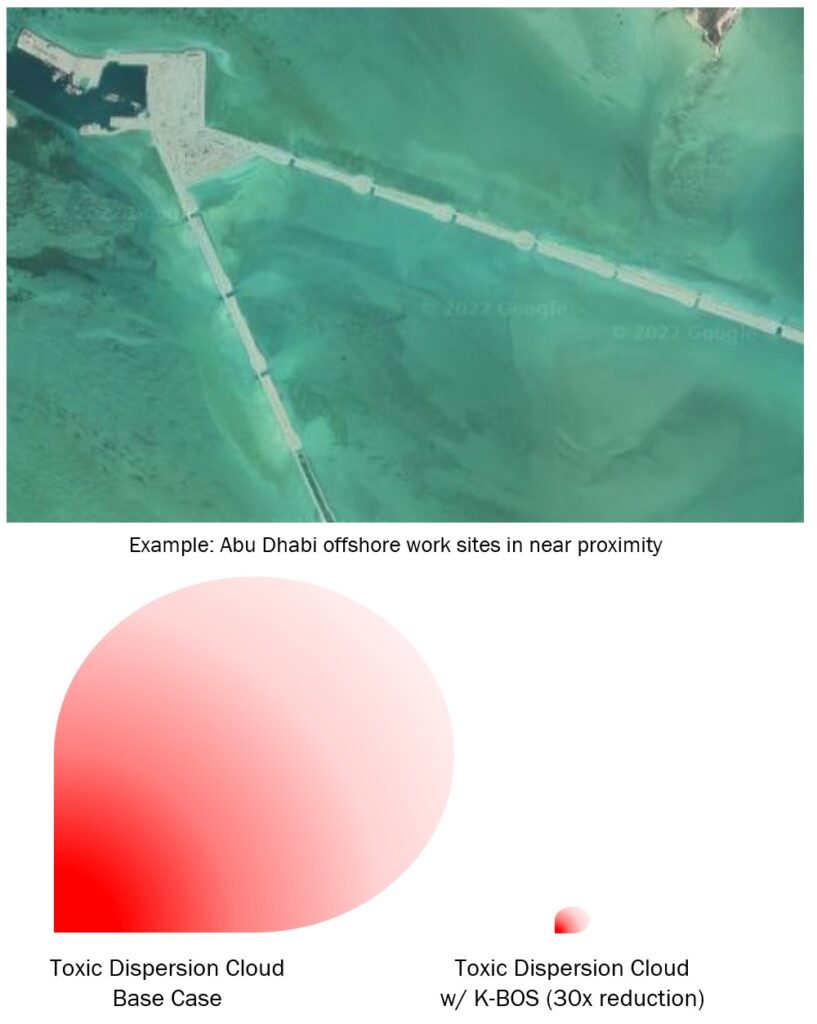

Shown above: Artificial drilling islands and sensitive environmental areas add to the complexity drilling operations. The illustration shows the relative size of a toxic dispersion cloud with a traditional BOPE vs the minimized toxic dispersion cloud (30x smaller) achievable with the K-BOS.

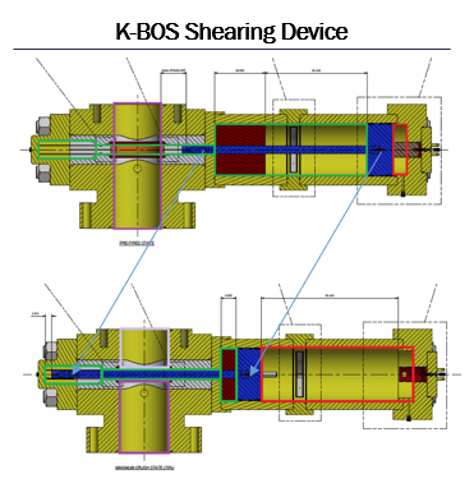

K-BOS® Sealing Technical Summary

- Pre-activation

- Firing bonnet/receiving bonnet seals isolated from wellbore

- Metal to Metal seals prior to activation:

Qualified for Unlimited H2S/CO2

Shown above: A cross sectional view of the K-BOS to illustrate how working components are isolated until activation, thus enabling compatibility with highly corrosive fluids without maintenance.

- Post-activation

- Upper And lower seals activated

- Zero Extrusion gap for elastomers

- Proprietary seal design

- Elastomers qualified to 50% H2S at 350F

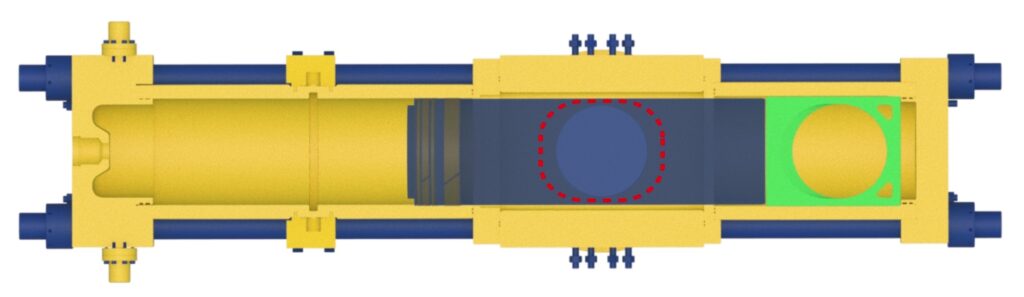

Shown above: The blue element illustrates the K-BOS gate as it fully sweeps the wellbore. The green element illustrates the shearing device after actuation. The red dashes illustrate the sealing area of the K-BOS.