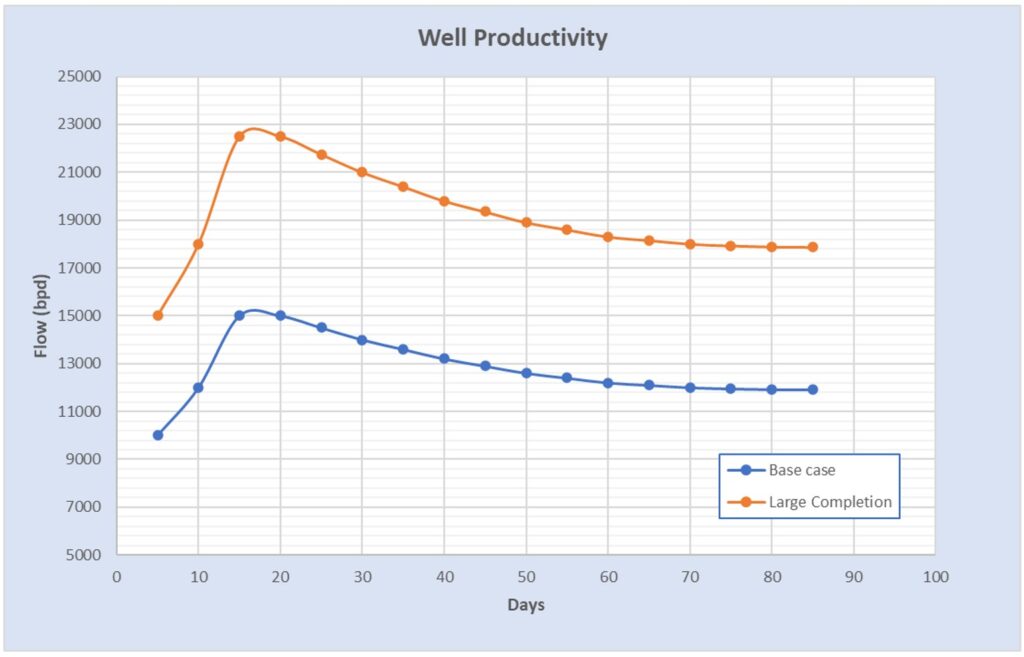

The K-BOS provides the ability to shear anything which enables drilling engineers to consider optimizations to a well design / completion or intervention. Opportunities such as landing a longer and heavier production casing into the hydrocarbon zone or even removing a casing string, may have been previously unacceptable due to unshearable exposure. Considering drilling systems with limited shearing capability like the 13-5/8″ 10,000 psi BOPs typical in surface drilling rigs, there are many fields where the K-BOS enables a revision of design limitations based on unshearable exposure resulting in cost reductions and enhancements to the production profile of a given reservoir.

Improved shear/seal capability and WC barrier enables:

- Larger/thicker-wall casing / production strings

- Completion components

- Tubing + control lines; gravel pack equipment

- Potential enabler for single trip completions

Value: Improved well productivity

- Larger production casing

- Larger tubing (especially in HPHT wells)

- Simplify control system for MUX SSTT

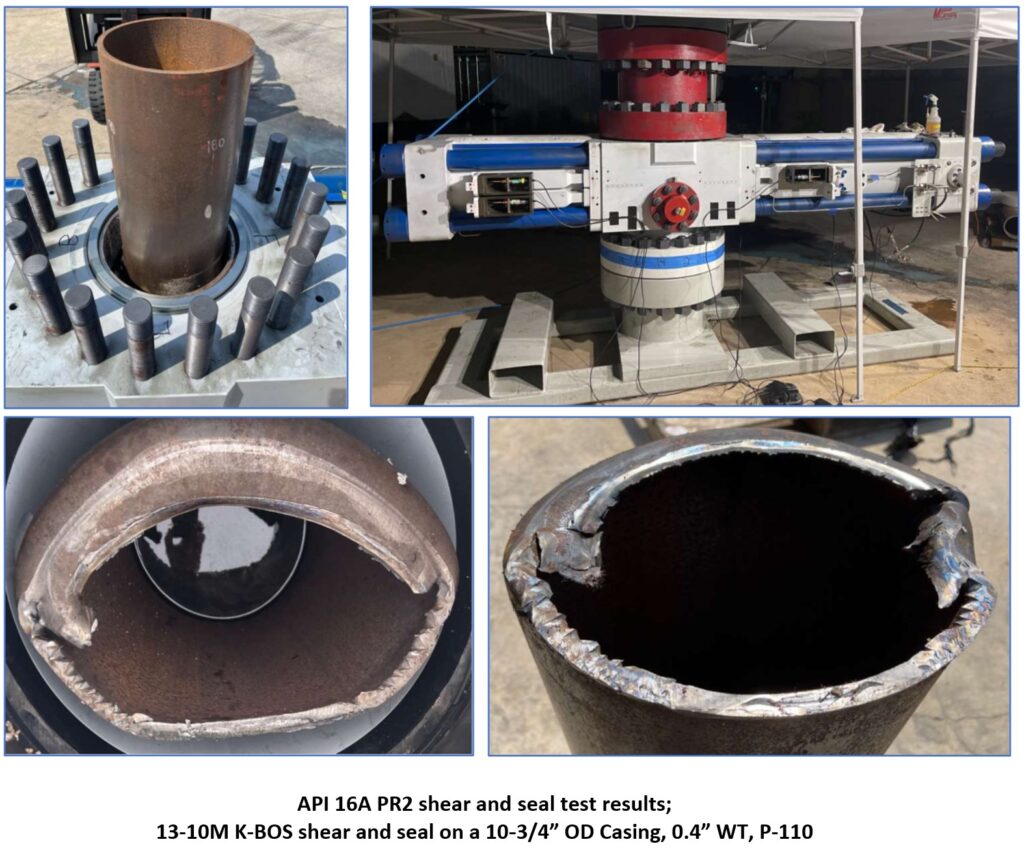

13-5/8″ 10,000 psi K-BOS examples:

Shown above: Shear test result using the 13-5/8″ 10,000 psi K-BOS

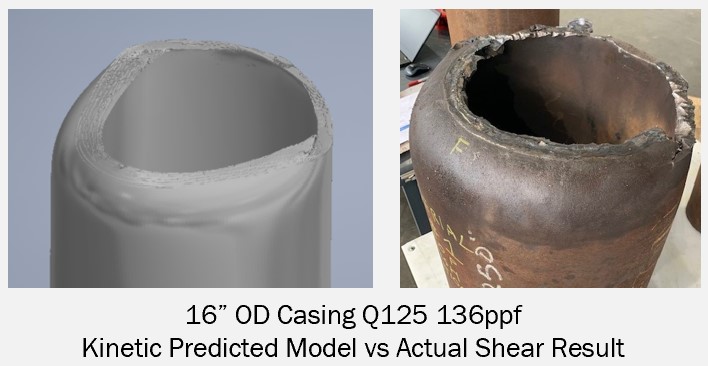

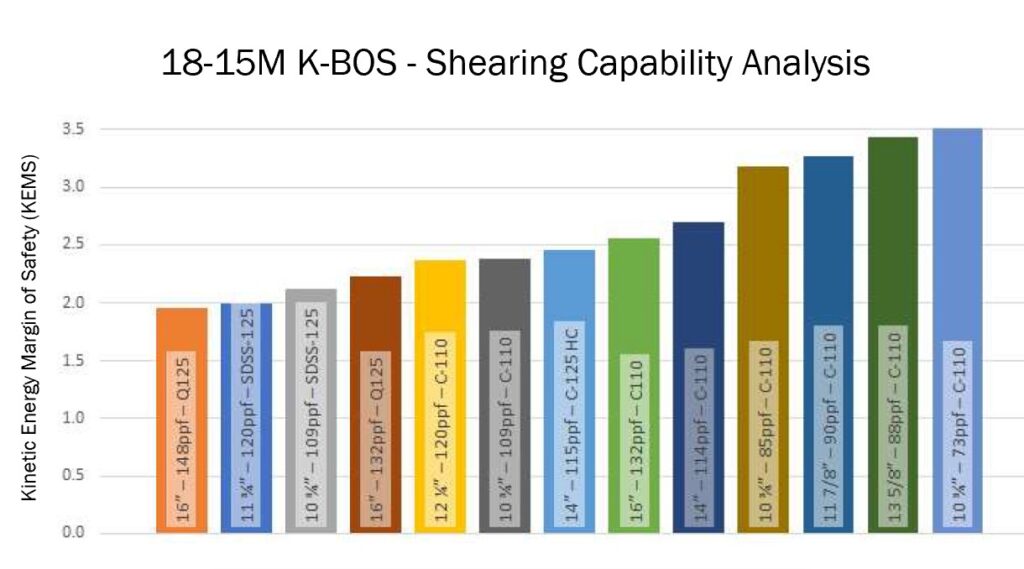

18-3/4″ 15,000 psi K-BOS examples:

Shown above: A predictive model of shearing performance (left) of the 18-3/4″ 15,000 psi K-BOS is compared to the results of a shear test (right) using a 16-1/4″ OD 136# Q125 casing.

Shown above: The Kinetic Energy margin of Safety for the 18-3/4″ 15,000 psi K-BOS is shown for a broad set of heavy casings. Notable shearable tubulars include the 10-3/4″ 109# SDSS125.

Shown above: The chart illustrates the relative increase in production achieved by increasing the internal diameter of a given well’s production tubing resulting in improved economics for an entire project.